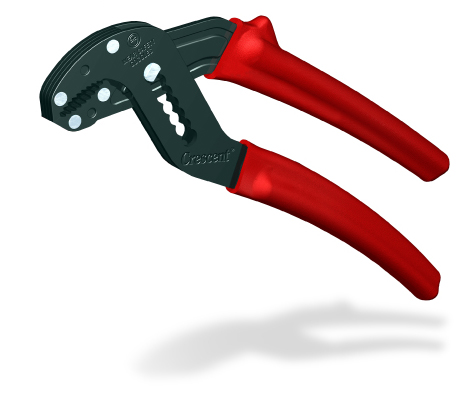

Cooper Tools are a trusted and respected manufacturer of wrenches and hand tools, but these American made products were finding it increasingly difficult to maintain market share as cheaper imports flooded the category.

/

1

2

·

·